Dust control

The use of Magnesium chloride for dust control

Magnesium chloride is a hygroscopic and a deliquescent compound. It attracts the moisture from the air, resists evaporation and binds fine dust particles to keep roads stabilized without the loss of aggregate.

A safe and potent material

Besides, Magnesium chloride can be safely used around plants and leaves no residue.

Magnesium chloride helps prevent surfaces from becoming uneven by protecting them from erosion. Indeed, the use of liquid Magnesium chloride makes unpaved surfaces harder and more compact.

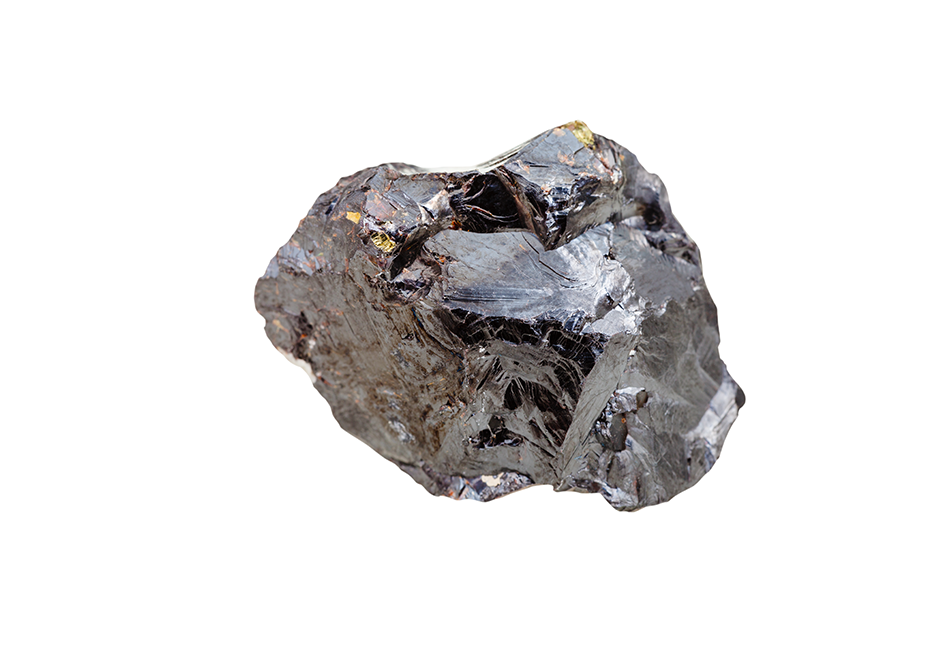

Hydrometallurgy

The use of CCM in hydrometallurgy

Magnesium oxide is a key reagent for the proper performance of hydrometallurgy process.

High purity Caustic Calcined Magnesite (CCM) is used to precipitate the hydroxide of valuable metals such as cobalt, nickel, uranium from acid leached solutions.

Valuable and powerful metal recovery

Magnesium oxide provides an excellent metal recovery performance and increase in the precipitate grade. The advantages of caustic calcined magnesia also include a gradual and proper control of the pH. The metal hydroxide particles grow and settle out faster. The metallic sludge generated is more concentrated in the solid. The dewatering process is easier compared to a sludge produced with lime or caustic soda.

Our grades are specifically designed for this application

Our specific grades offer :

- Low impurity content

- High reactivity

- Extremely fine particle size distribution

Our track record positions these grades as « best in class » for this demanding application.

Drilling

The use of Magnesium in drilling process

The drilling operations demand a high knowledge of characteristics of the drilling muds, that contains many additives. Their complex composition can modify the fluid density, rheology, or alkalinity. Magnesium can allow to master these parameters.

Magnesium controls fluid density, rheology, or alkalinity

- In brine drilling mud, it plays the role of a scouring agent, used to keep the annulus clean. It also helps neutralize acid gases released by the drilling process.

- Fluid alkalinity can be controlled by the use of Magnesium, particularly in clay-free polymer based fluids.

- To manage the rheology of drilling mud, Attapulgite can also be used. Combined with small quantities (approximately 2% by weight) of Magnesium oxide, it allows an higher fluid viscosity.

Our specifically designed CCM and DBM grades

Our specific grades offer the consistency expected for this application. We also offer to our customers the logistics setup they require, including a stringent quality process, focusing on full traceability of the delivered products.

Select a topic below to learn more about our other solutions for the industry :